Oil & Process Industry

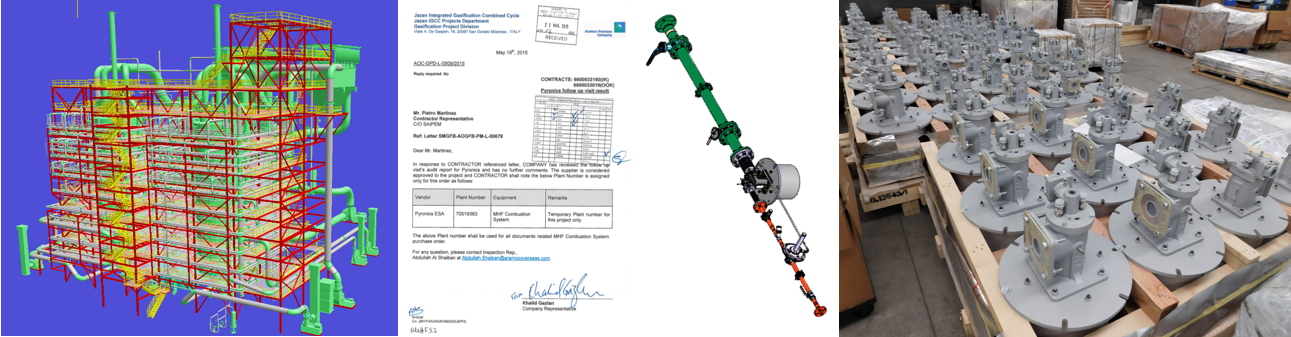

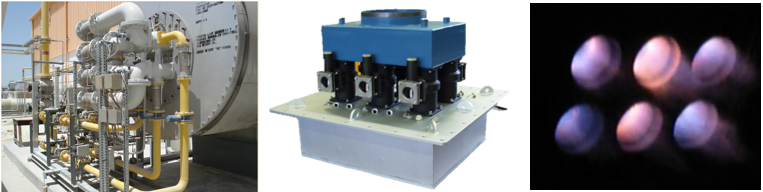

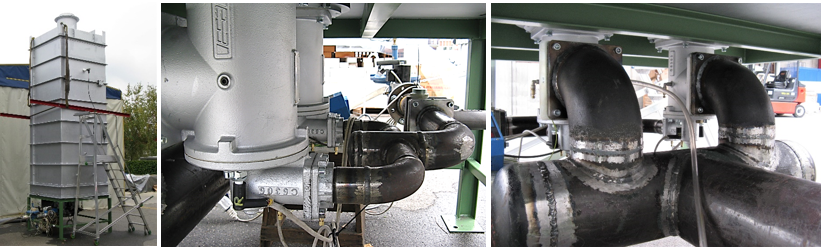

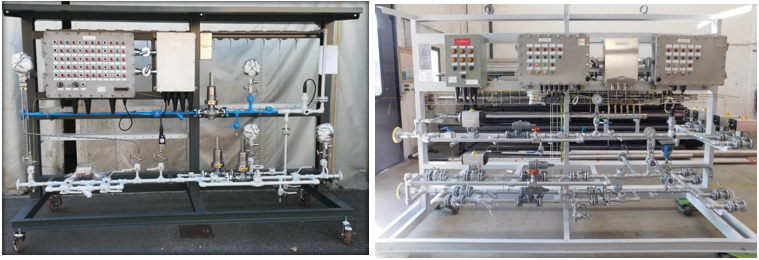

In Oil & Gas, Chemical and generally in”process applications”, ESA works as a system Integrator for EPC and OEM companies and offers its vast experience, its existing product lines and its ability to develop innovative and complete solutions: in particular, fuel feeding skids for liquid or gaseous fuels and flare ignition skids, also developing electrical panels and automation.

ESA manufactures a wide range of combustion systems used in various heating applications:

• THERMAL OXIDIZERS/ REGENERATIVE THERMAL OXIDIZERS

• DIRECT FIRED HEATERS

• INDIRECT BATH HEATERS

• GLYCOL RE-BOILERS

• DRYERS

• FERTILIZERS

• VARIOUS APPLICATIONS IN MINING INDUSTRY

The models we offer are of two types:

– Burners derived from the standard range or with minimal customizations.

– Burners designed “on demand” up to 40 MW, with natural or forced draft.

|

For custom made burners, ESA can also offer preliminary CFD control by FLUENT ® and validation with real test into our Combustion Center. All activities regarding the design, assembling, refractory blocks are completed within the Company.

ESA furthermore offers fully engineered solutions according to customer specification and in conformity with the applying legislations : EN 746, NFPA 85/86, PED 2014/68/UE, ASME IX ATEX 2014/34/UE, IEC 61508/61511 SIL etc.).

These activities are also carried out internally thanks to our engineering and automation departments. And our welding department with certified operators.

Each project is developed in team in collaboration with multiple actors: the main contractor, the EPC, the end user, the control body …, entrusted to the responsibility of a project manager who works according to ISO procedures, in order to track and record each activity, define the project GANT, supervise, update and reprogram the order activities.

If external suppliers are to be used, it should be noted that ESA boasts long-term relationships (in some cases over ten years) with suppliers carefully selected on the basis of their ability to work in substantial and formal terms in compliance with the dictates and Quality procedures.