Copper & Brass

ESA experience in copper is mostly, but not exclusively, concentrated in the design of combustion systems and burner for shaft melting furnaces, holding furnaces, various ancillary systems and in downstream processing of copper semifinished products.

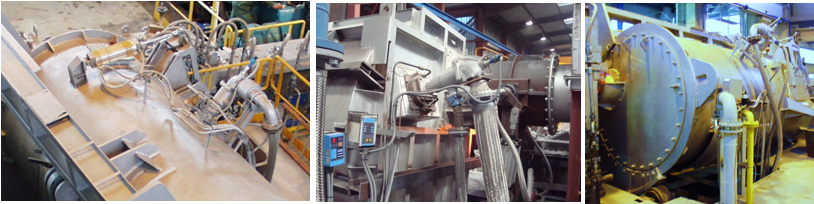

SHAFT FURNACE FOR SECONDARY COPPER

Shaft furnace is used to manufacture copper rods of electronic quality . It is a essentially a cylinder charged from the top of copper cathodes, first quality copper scrap, wasted copper wire and wirebar. Burners are mounted radially around the lower shaft section, in two of more rows to provide the melting energy for different capacities. The waste gases travel upwards through the shaft to preheat the solid scrap in the upper part. The liquid copper can be fed to the next process step by means of a ladle or launder.

In order to produce “electronic” quality copper the heating system must answer to various requirements:

1) be accurate in controlling the inner furnace atmosphere, that must avoid oxygen presence and his dissolution into the molten metal.

2) limit the possible obstruction caused by molten metal around the burners’ nozzle.

3) burners must generate a countecurrent stream of flue gases to melt progressively the load

4) the flame must not be too long as there is few space at the bottom of the shaft.

These problems brought to the development of a family s of highly specific burners, featured by feeding of premixed fuel which allows a better control of the O2 and

with a short and speed flame.

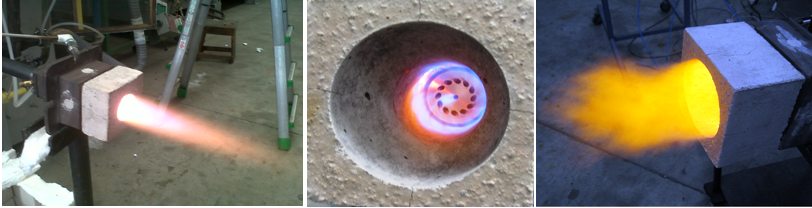

E- THERM PRE MIX HIGH VELOCITY BURNERS

E-Therms are featured by a complete fuel mixing very close to the nozzle. They produce a tight and speed flame that allows for high heat penetration and temperature uniformity inside the combustion chamber.

The refractory block, particularly, is provided of a special design which allows to improve the dynamic of hot flows, which, in conjunction to the furnace geometry, generates a progressive melting of copper, with very low energy consumption.

LAUNDERS (Molten Copper transport channel) and HOLDING furnaces

The main combustion problem of launders and “pure” holding furnaces is linked to the requirement of keeping a fluid mass of metal constantly and homogeneously heated.

ESA offers several possibilities according to customer requirements, but the main is the special ENR burner .

ENR premixed BURNER SA very flexible typology of premixed burner, being available in a range from 10 Kwh to 3MW and for temperatures from 100° to 1150°. They are featured by a turbulent thought short flame, which insure full combustion of oxygen and, high temperatures levels close to the burner exit in order to limit the risk of obstruction by molten copper lame. Premixing is carried out by an external mixer like our Flomixer.

REVERBERATORY REFINING FURNACES

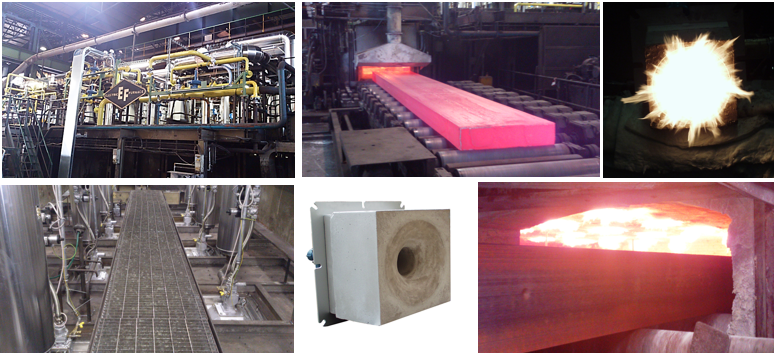

According to the quality of copper, the kind of treatments requested ,it is possible to find a vast number of possible furnaces. Different for geometry and functions, the main combustion requirement in common remain to reach a wide and uniform energy distribution over the whole inner surface of molten metal. ESA can help in any situation with the right burner, ignition system, skid and automation.

For istance more and more requested as of now is the Air-Oxy fuel burner AGO Nxt, which, being able to switch from oxygen to air according to heat process requirements, provides superior flexibility and energy saving capability.

COPPER WALKINK’ BEAM FURNACE (“PASSO PELLEGRINO”)

As sample of one of downstream processing of semifinished products here it is shown the use of our ESW flat flame burner into a continuous line for slab processing.