Zinc & Galvanisation

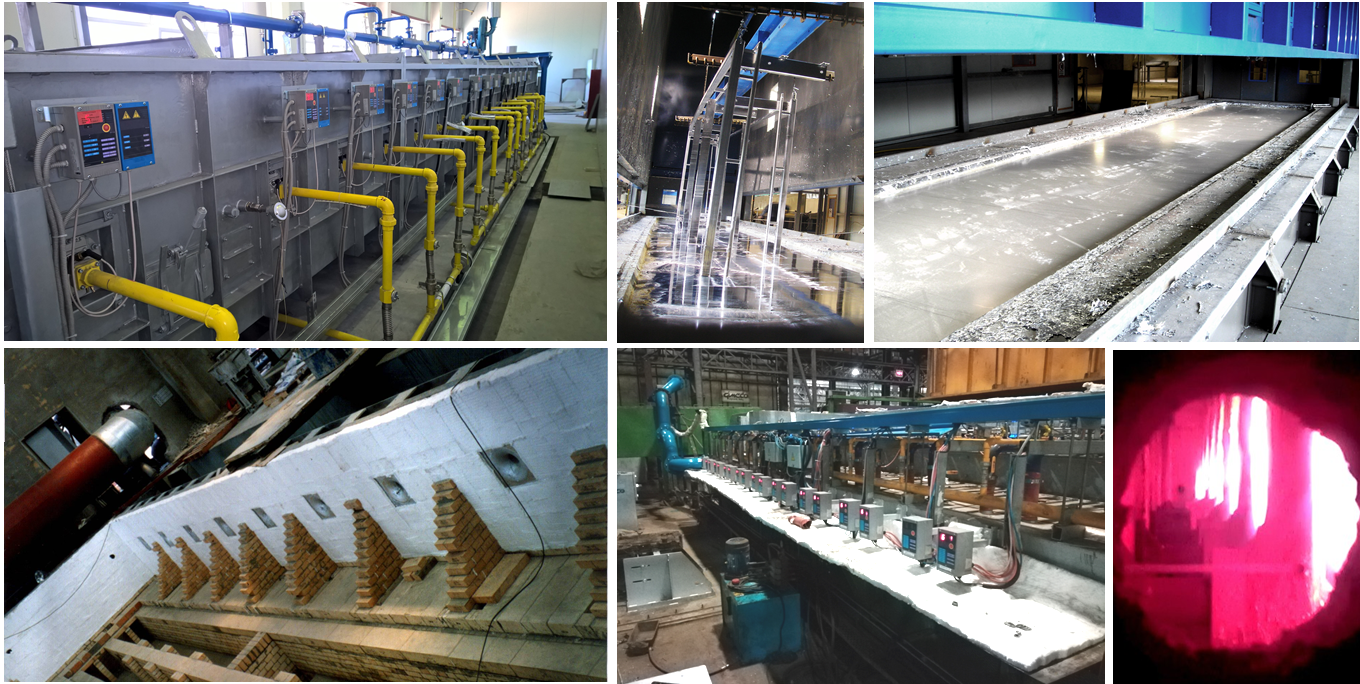

ESA has a long experience and provides burners and complete combustion solutions for hot dip galvanizing process,

Several type of burners can be used according to furnace type (ceramic bath, steel kettle…) .

ESA SIDEWALL BURNERS (ESW)

One of the most common typology of burners used in zinc furnaces is the sidewall ESW burner, that, providing a flat flame, reduce the risk of hot spot creation on the zinc pot and consequent risks of damages and maintenance shutdowns.

Sidewall Burners ESW are available in capacities from 90 to 1400 KW. One of their main important feature is their high efficiency levels as, due to the geometry and design, the flame reaches extremely high radiant component and flat flame shape in all the turn-down of the burner.

The very wide turndown, the precision, also, in conjunction with a pneumatic modulating system (as shown in the photos) allows strong energy savings, as it helps to adapt automatically the gas flow to the process heat requirements.

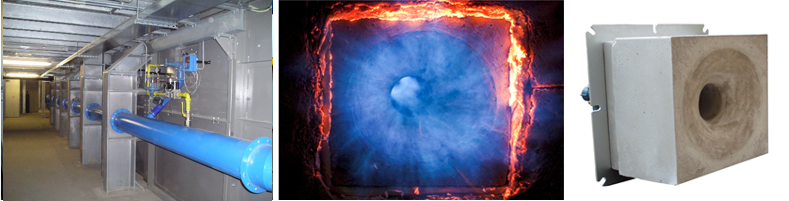

SELF RECUPERATIVE BURNERS FOR REVERBERATORY FURNACE

Refractory built hot dip galvanizing furnaces for zinc bath are featured by a concentrated heat distribution, with less burners of higher power that fire tangentially over the melted zinc surface. For this reason, it becomes extremely convenient the use of energy saving models as the REKO-FF-NxT, high velocity, self- recuperative free flame burners.These burners combines great flexibility and easy installation with extreme energy efficiency levels thanks to the integrated heat recovery system: an heat exchanger which use the exhaust heat to pre-heat the combustion air.

The burner, in the previous version (REKO-SIK) or in the new patented one, (REKO-SIK-NxT), completely casted, assures robustness and high resistance to heat and oxidation.

The heat exchanger element in this application is preferably in alloy steel and its special design allows the optimization of heat transfer from the combustion products to the combustive air. This choice allows the burner to be used with maximum chamber temperature of up to1300°C under direct heating conditions. REKO-SIK-NxT free flame burners are available in several capacities from 30 to 400 KW

In the matter of REKO performances, ESA has been chosen as combustion supplier by company GIMECO into the E-FURNACE Project, which obtained the grants of European Community HORIZON2020. ESA took care of combustion side, reaching unmatched combustion goals (fuel saving up to 30% compared to cold air burners, reduced NOx, CO2 emissions…) with the REKO-SIK-FF burner.

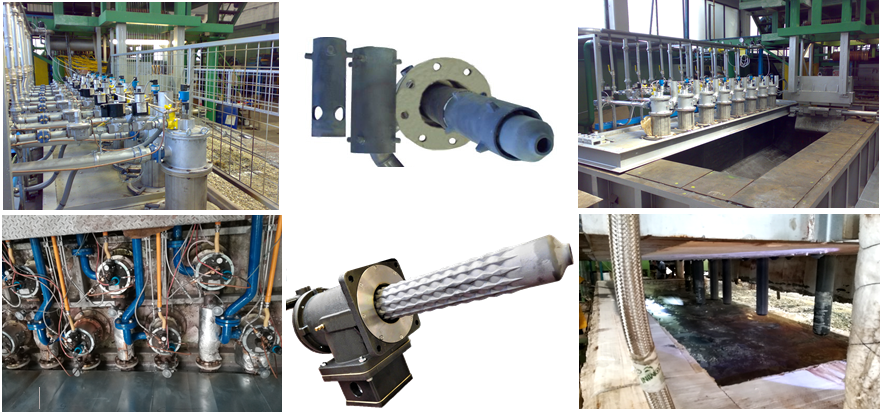

RADIANT TUBES SELF RECUPERATIVE BURNERS « REKO-SIK-RT » FOR COMBUSTION BY IMMERSION

ESA provides solution where straight-type radiant tubes in ceramic materials are directly immerged into the molten metal. For this technology REKO-SIK-NxT-RT self-recuperative burners are recommended.

DRYING FURNACES

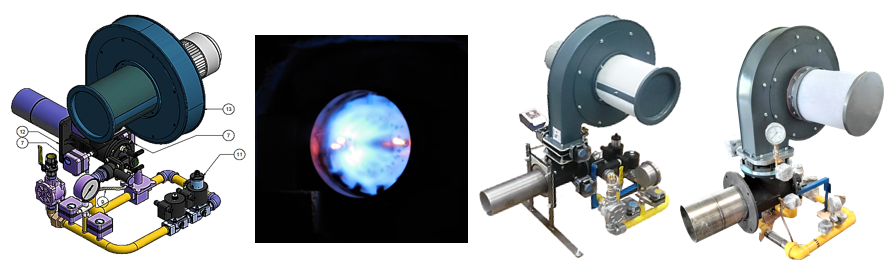

The heat requirement in a drying furnace is low, as the temperatures are between 70°C and 150°C. These applications commonly use packaged burners, that is, are burners that integrate combustion air blower and a complete fuel regulation line.

ESA has two solutions:

a) EPB packaged metallic burner. The system is modulating through a butterfly valve actuated by our ESA SERIO motor, while stoichiometry is granted by the zero-governor to adjust pneumatically the gas flow according to the air flow. The gas line is EN746.compliant and marked CE, being a semi-machines. EPB eliminates the need to install dedicated gas and air pipelines skids.

b) FC packaged burner supplies a fixed flow of combustion air and is adjusted only by operating on the gas flow-rate. The metal cone, the design of the burner and the continuous air inflow allow obtaining exhaust suitable for low temperatures applications.